Vibratory grinding is used mainly in the surface treatment of complex metal workpieces. It is particularly suitable for products which have hard-to-reach places, e.g. Rim stars that can not be reached with polishing wheels. The production pieces are placed in an aqueous solution together with grinding wheels and additives. This causes material removal on the workpiece.

What is vibratory grinding/finishing for high-gloss surfaces?

Nature shows us the way – sand and water grind even rough rocks to smooth, perfectly rounded stones. In modern production technology, the process is accelerated many times over.

Application areas

The vibratory finishing process, also known as trowalizing, can process surfaces in different ways.

The following goals can be achieved:

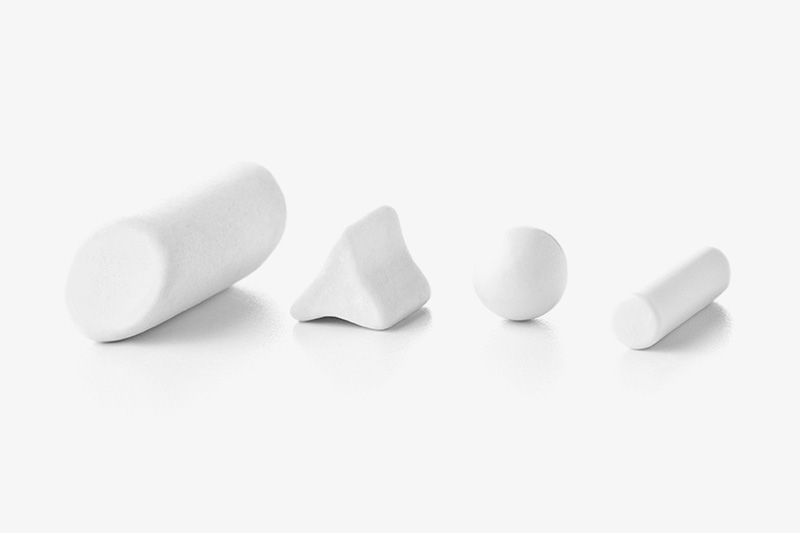

Special polishing and grinding wheels

Grinding and polishing bodies are of great importance for the vibratory finishing process. Depending on the requirements, different methods are used, as the desired result depends heavily on the correct grinding wheel.

Compounds

Workpieces can not only be processed with grinding wheels but also with compounds during vibratory finishing. Compounds are used for cleaning, degreasing or as corrosion protection for the workpieces.

The following advantages are associated with compounds:

The advantages

When refining rims, vibratory grinding has clear advantages over the manual treatment of the production item.

The advantages at a glance: