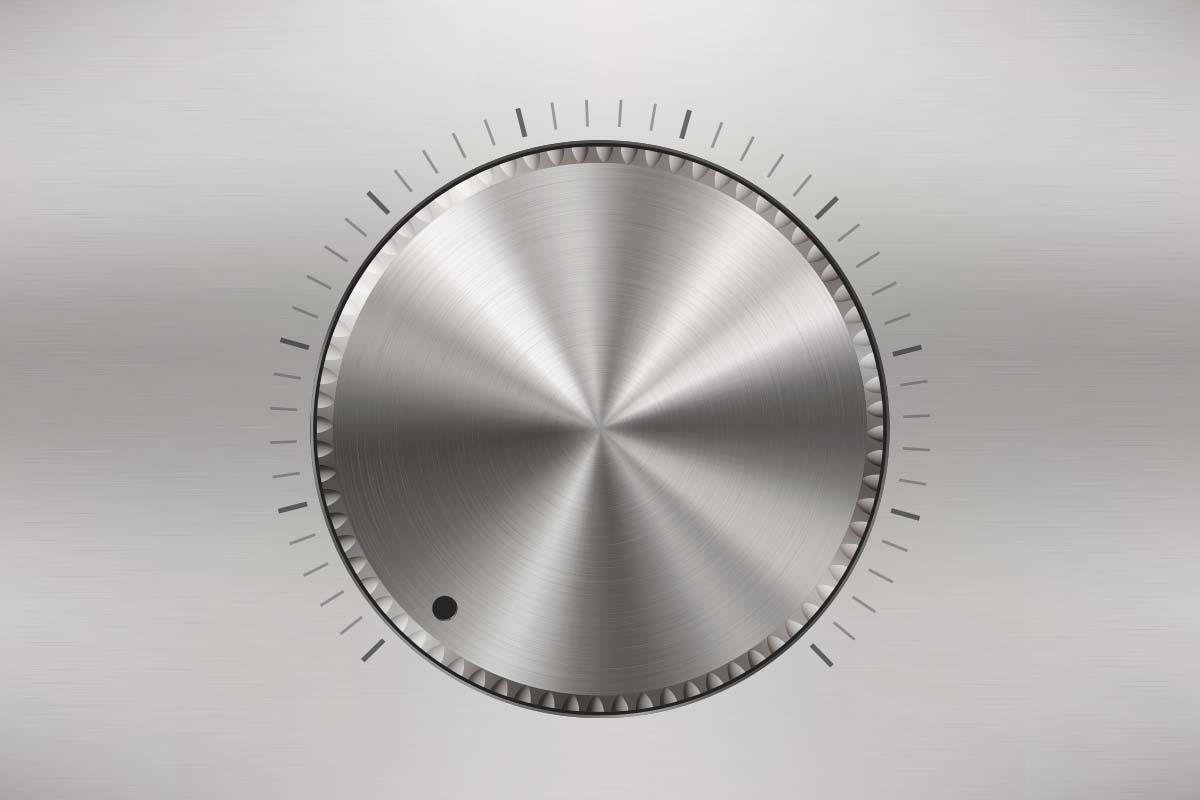

A precisely center-aligned circular grinding with a shadow-free, even and homogeneous grinding pattern requires expertise and precision in the finishing of metal surfaces. This high level of processing impresses customers from a wide range of industries and is based on our many years of experience and the particularly high accuracy of our processing tools.

What does circular grinding mean?

Concentric circular grinding refers to the centric grinding, brushing and matting of metal parts. This demanding machining technique not only requires precise alignment of the grinding tool in relation to the center of the round workpiece, but also extensive specialist knowledge and experience. The rotation of the workpiece, the machine speed, the movement speed of the robot, the contact pressure as well as the cooling and the use of high-quality abrasives must be optimally coordinated. This is crucial to to avoid visible grinding marks and shadows.

Round grinding with the highest precision

The use of our robot-supported system technology enables consistently high quality and accuracy while at the same time optimizing costs in series production. Of course, we manufacture according to your desired Ra value.

Our range of services goes beyond pure surface processing of metals. If desired, we act as a system supplier and, thanks to our supplier network, we can offer you everything from a single source – including final assembly.

Individual processing of

various round parts

Depending on the properties of the round part to be processed and your specific requirements, we adapt our production processes accordingly and thus achieve the perfect result, especially for the transitions between lid and outer surfaces, which can be made round or sharp-edged if desired.